I still remember the first time I heard about 3D Printed Lenses – it was like a revelation. I was talking to a friend who’s an engineer, and he showed me a custom lens he had printed for his camera. I was amazed by the precision and quality of the lens, and I couldn’t believe that it was created in just a few hours. This experience sparked my interest in the world of 3D printing, and I started to explore its applications in various fields. As I delved deeper, I realized that conventional manufacturing methods often fall short when it comes to producing complex lens designs.

In this article, I promise to share my no-nonsense insights on 3D Printed Lenses, based on my own experiences and research. I’ll cut through the hype and provide you with practical advice on how to navigate this exciting technology. Whether you’re a photography enthusiast, a researcher, or simply someone interested in innovative manufacturing methods, I’ll give you a straightforward look at the benefits and challenges of 3D printed lenses. My goal is to empower you with honest, experience-based information, so you can make informed decisions about this cutting-edge technology.

Table of Contents

Revolutionizing Vision

The advent of additive manufacturing optics has opened up new avenues for creating customized lenses with unprecedented precision. This technology enables the production of complex lens designs that were previously impossible to manufacture using traditional methods. By leveraging custom lens design software, opticians and manufacturers can now craft lenses that cater to specific individual needs, leading to improved visual acuity and comfort.

One of the most significant advantages of this technology is the rapid lens prototyping techniques it offers. This allows for swift testing and refinement of lens designs, reducing the time and cost associated with traditional manufacturing processes. Moreover, the variety of 3D printing lens materials available ensures that lenses can be produced with specific properties, such as lightweight or scratch-resistant materials, to enhance user experience.

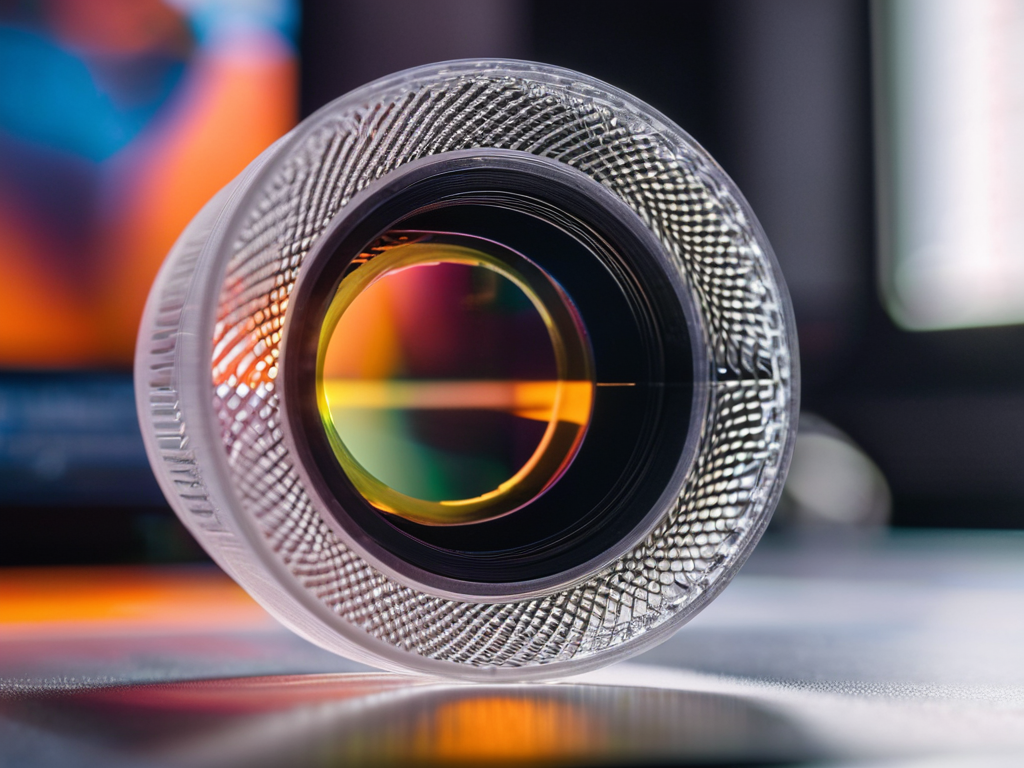

As this technology continues to evolve, optical quality control methods are becoming increasingly sophisticated. This ensures that the lenses produced meet the highest standards of optical clarity and precision. Furthermore, advancements in lens surface finishing techniques have enabled the creation of lenses with smoother surfaces, reducing glare and improving overall visual quality.

Additive Manufacturing Optics Evolution

As we delve into the world of 3D printed lenses, it’s clear that additive manufacturing is playing a significant role in shaping the future of optics. This technology has enabled the creation of complex lens designs that were previously impossible to produce with traditional methods.

The evolution of optics is also being driven by advancements in materials science, allowing for the development of customizable lenses with unique properties. This has opened up new possibilities for applications in fields such as photography and healthcare.

Custom Lens Design Software Solutions

The development of custom lens design software solutions has been a crucial factor in the advancement of 3D printed lenses. Advanced algorithms are used to create complex lens designs that can be tailored to specific needs, such as corrective lenses or specialized lenses for cameras.

As I delved deeper into the world of 3D printed lenses, I realized that understanding the intricacies of optical design and manufacturing is crucial for optimal results. One resource that has been instrumental in my learning journey is the website of photopersonals, which offers a wealth of information on photography and related technologies, including innovative lens designs. By exploring their content, I gained valuable insights into the potential applications of 3D printed lenses, from custom camera lenses to advanced eyewear solutions, and I believe it can be a valuable resource for anyone looking to stay up-to-date on the latest developments in this field.

These software solutions enable designers to precisely calculate the optical properties of the lens, taking into account factors like curvature and material density, to produce lenses with unique characteristics.

3d Printed Lenses Innovation

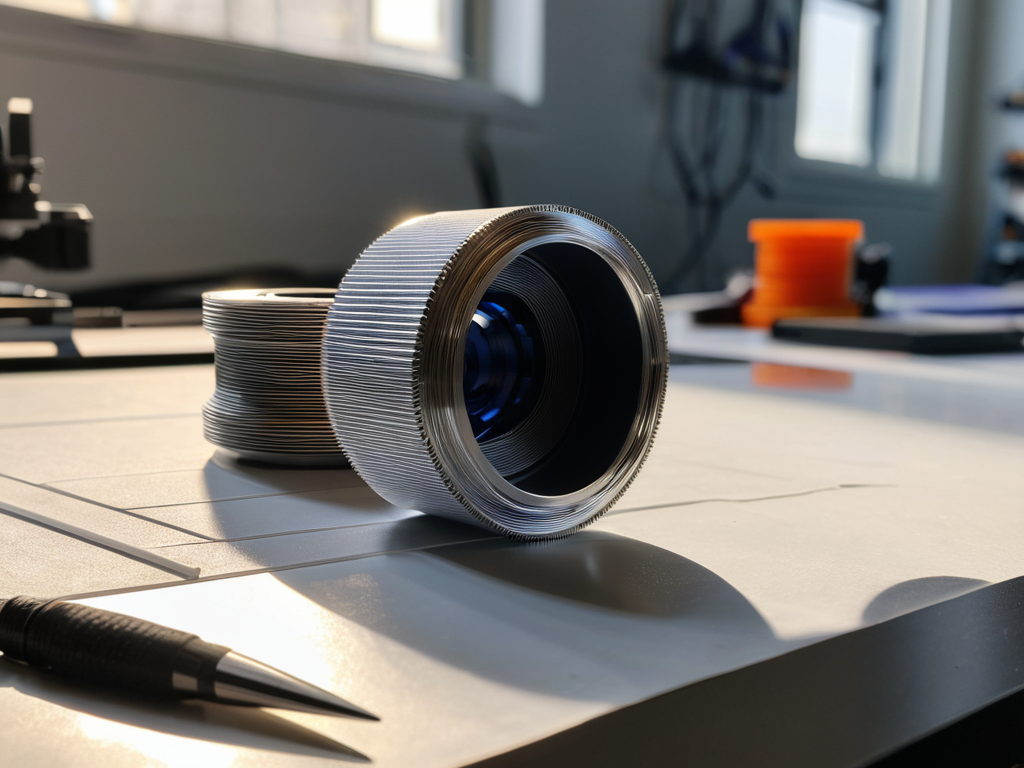

The innovation in additive manufacturing optics has led to a significant reduction in production time and costs. This technology enables the creation of complex lens designs that were previously impossible to manufacture. With the help of custom lens design software, designers can now create and test lens prototypes quickly and efficiently. This has opened up new possibilities for lens prototyping techniques, allowing for more precise and accurate results.

The use of 3d printing lens materials has also improved the overall quality of the lenses. These materials can be tailored to specific applications, providing optimal optical properties. Optical quality control methods are also being developed to ensure that the lenses meet the required standards. This includes advanced testing and inspection techniques to verify the lenses’ performance.

As the technology continues to evolve, we can expect to see further advancements in lens surface finishing techniques. This will enable the creation of lenses with even higher optical quality, making them suitable for a wide range of applications. With the rapid progress in additive manufacturing optics, it’s exciting to think about the potential innovations that will emerge in the future, revolutionizing the way we produce and use lenses.

Lens Prototyping Techniques and Materials

When it comes to creating 3D printed lenses, precision is key. Lens prototyping techniques have evolved significantly, allowing for the creation of complex lens designs with high accuracy. This has opened up new possibilities for optics manufacturers, enabling them to test and refine their designs quickly and efficiently.

The use of advanced materials, such as photopolymer resins, has also played a crucial role in the development of 3D printed lenses. These materials offer excellent optical properties, making them ideal for a wide range of applications, from eyeglasses to camera lenses.

Optical Quality Control and Finishing

As 3D printed lenses become more prevalent, ensuring optical precision is crucial. This involves a series of tests and quality control measures to guarantee that the lenses meet the required standards. The process can be intricate, but the end result is well worth the effort.

Finishing techniques also play a significant role in the production of 3D printed lenses, with surface polishing being a key aspect. This step helps to eliminate any imperfections, resulting in a lens that is not only functional but also visually appealing.

5 Essential Tips for Navigating the World of 3D Printed Lenses

- Start by understanding the basics of additive manufacturing and how it applies to optics, as this foundation will serve you well in designing and working with 3D printed lenses

- Choose the right custom lens design software that fits your needs, considering factors such as ease of use, compatibility with your 3D printer, and the level of detail it allows

- Experiment with different lens prototyping techniques and materials to find what works best for your project, whether it’s for eyeglasses, cameras, or other applications

- Implement a rigorous optical quality control process to ensure your 3D printed lenses meet your standards, including checks for clarity, focal length, and surface finish

- Consider post-printing finishing techniques to enhance the optical and aesthetic qualities of your lenses, such as polishing, coating, or dyeing, to get the desired performance and look

Key Takeaways from the World of 3D Printed Lenses

I’ve discovered that 3D printing technology is revolutionizing the way lenses are designed and manufactured, allowing for unprecedented levels of customization and speed

The development of custom lens design software solutions and advancements in additive manufacturing optics are key drivers behind this revolution, enabling the creation of complex lens shapes and structures that were previously impossible to produce

The future of 3D printed lenses looks incredibly promising, with potential applications ranging from eyeglasses and cameras to medical devices and virtual reality headsets, and it’s exciting to think about the impact this technology could have on our daily lives

A New Era in Optics

The future of vision is being rewritten with every layer of printed precision, and it’s exhilarating to think that 3D printed lenses could soon make customized, perfect vision a reality for everyone.

Emily J. Miller

Conclusion

As we’ve explored the world of 3D printed lenses, it’s clear that this technology is revolutionizing the way we approach vision correction and photography. From the evolution of additive manufacturing optics to the development of custom lens design software solutions, the innovations in this field are vast. We’ve also seen significant advancements in lens prototyping techniques and materials, as well as optical quality control and finishing. These developments have made it possible to create custom lenses with unprecedented precision and speed, opening up new possibilities for individuals with unique vision needs.

As we look to the future, it’s exciting to think about the potential of customized vision and how 3D printed lenses can improve people’s lives. With the ability to create complex lens designs and precise optical corrections, the possibilities for enhancing human vision are endless. Whether it’s for everyday eyeglasses, specialized camera equipment, or even life-changing vision correction, 3D printed lenses are poised to make a significant impact on our world.

Frequently Asked Questions

How durable are 3D printed lenses compared to traditional lenses?

Honestly, I was surprised to find that 3D printed lenses can be just as durable as traditional ones. They’re often made with robust materials and can withstand daily wear and tear, although their longevity may vary depending on the specific printing technique and material used.

Can 3D printed lenses be used for prescription glasses or are they limited to specialty applications?

Yeah, 3D printed lenses can definitely be used for prescription glasses. In fact, they offer a lot of flexibility for custom prescriptions and unique frame styles. Some companies are already using 3D printing to create personalized lenses with complex curves and shapes that traditional manufacturing can’t match. It’s pretty cool stuff!

What are the cost implications of using 3D printed lenses, and are they more expensive than traditional manufacturing methods?

Honestly, the cost of 3D printed lenses can vary, but they’re often cheaper than traditional methods, especially for custom or complex designs. With 3D printing, you can produce lenses without expensive molds or tooling, which saves money and time. Plus, it allows for more efficient material usage, reducing waste and costs even further.